The making of RRRolling Stones

The League's Sarah Wesseler gives a behind-the-scenes look at the winner of the 2018 Folly/Function competition.

Folly/Function is an annual juried competition engaging architects to design and build a project for Socrates Sculpture Park. In 2018, entrants were asked to propose movable outdoor seating.

RRRolling Stones, a design by Ithaca, New York, firm HANNAH, won the competition.

For the last few weeks, a nondescript warehouse on the outskirts of Ithaca, New York, has been dominated by a giant gantry printer squirting wet concrete into vaguely dog-like shapes.

The brainchild of designers Leslie Lok and Sasa Zivkovic, cofounders of HANNAH, the project is the latest in a series exploring the architectural potential of 3D printing at full scale. This time, the end product is destined for a popular sculpture park on the Queens waterfront.

Here’s the story behind RRRolling Stones.

Robotic Brutalism?

Lok and Zivkovic have been experimenting with 3D printing since 2011, starting with self-built desktop machines and moving to larger sizes over time. Rejecting the notion that that the technique is stylistically neutral, they believe that the combination of process and printing material lends itself to particular design approaches.

After exploring various materials, the duo became convinced that 3D-printed concrete offers especially fertile territory for investigation. Together with students at the Cornell Robotic Construction Laboratory (RCL), which Zivkovic directs, they built a large-scale printer to enable further study. (The printer technology is not particularly complex, Lok said; RCL found the information needed to construct the machine on the internet.)

The next step involved finding a concrete mix that would remain wet long enough to print while still maintaining the desired shape during extrusion. Determined to use ingredients that could be purchased at any hardware store, they settled on a base of sand, mason mix, Portland cement, and water. They then worked with Cornell students to test different supplementary materials, from nylon fiber to superplasticizer, to optimize the mix for strength and workability.

Just add water: The base materials for HANNAH's concrete are sand, mason mix, and Portland cement. Credit: HANNAH

“Our team tried out different ratios of materials and test printed with the various mixtures. [The samples pictured below] are all failures, in a way,” Lok said. Some proved too wet, quickly losing their shape after printing; others were too dry and produced clumpy, non-continuous lines.

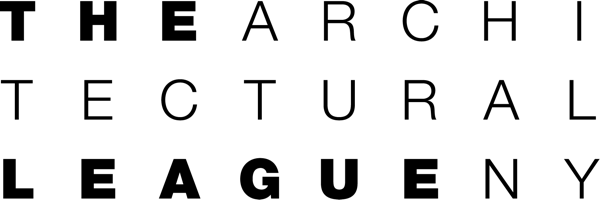

Once they had a working mix, Lok and Zivkovic explored its potential to produce innovative versions of standard architectural elements like columns and flooring. Their Additive Architectural Elements project, which generated seven full-scale prototypes and dozens more models, revealed the utility of design strategies such as corbelling, printing in section, and altering geometries to align with the structural logic of the fabrication process.

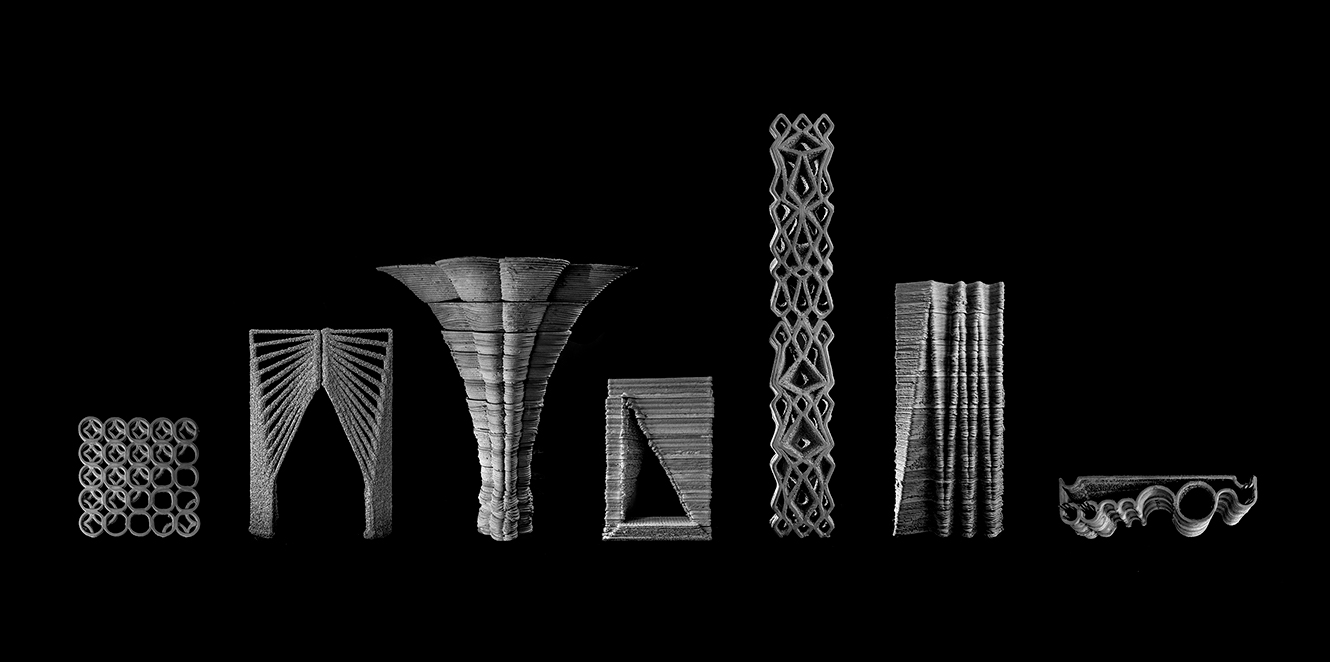

HANNAH’s second 3D-printed concrete project, a cabin currently in construction in Ithaca, focuses on printing at a building scale instead of working with discrete architectural parts.

HANNAH’s Ithaca cabin. Left: Custom rebar cage within 3D-printed formwork. Top right: Printed cabin base incorporating a chimney, table, and seating element. (HANNAH is building a habitable wooden portion atop the concrete platform; the wood envelope is being robotically sliced out of logs.) Bottom right: Detail of the cabin’s corbelled underside. Credit: HANNAH

Designing a functional folly

When Lok and Zivkovic read the 2018 Folly/Function competition brief, they saw an opportunity to explore another side of 3D-printed concrete by creating objects for the public to engage with.

The RRRolling Stones design grew out of the fact that 3D printing lends itself naturally to a sectional approach. Since the printer essentially draws concrete lines, it made sense to create a chair whose sectional profile consists of differently shaped lines that provide multiple seating options. To switch from one kind of seat to another, users would simply roll the chair.

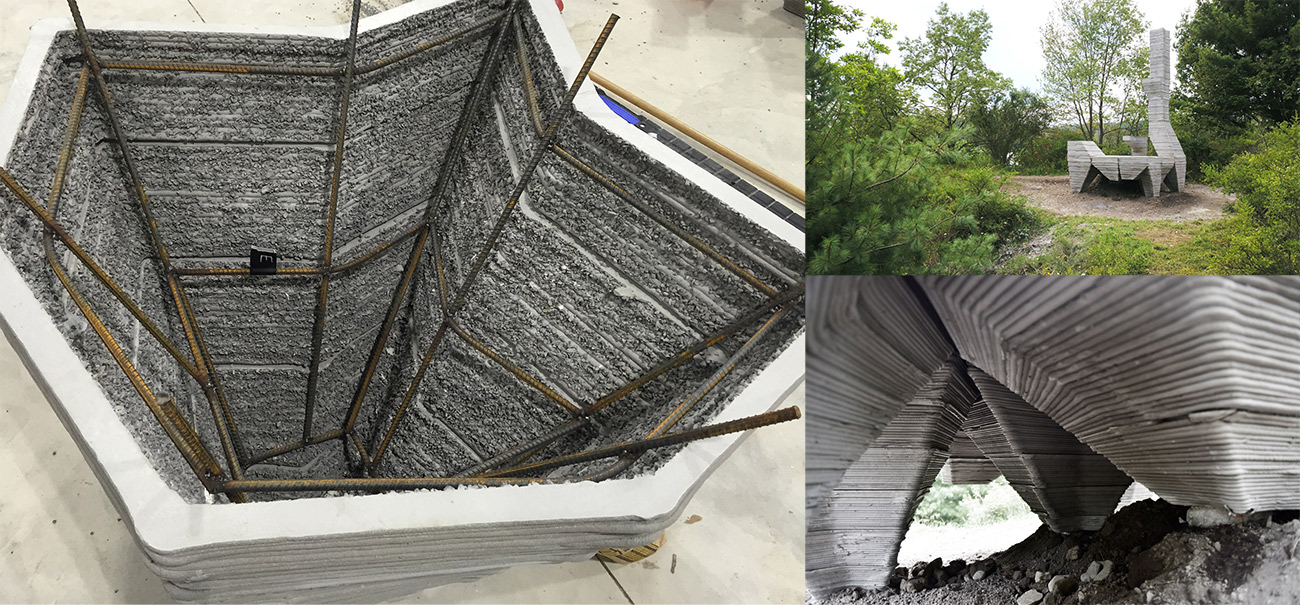

During the competition phase, Lok and Zivkovic focused the design effort on questions of form and constructability. When preparing the final pieces for public use, however, they paid special attention to the need to carry heavy loads. They experimented with sandwiching different reinforcement materials between the printed concrete layers in order to strengthen the chairs.

The design team tested various methods for strengthening the seats. Clockwise from top left: Single concrete layer rebar reinforcement; additional fiberglass reinforcement; double concrete layer steel rebar reinforcement; steel fiber reinforcement. Credit: HANNAH

After testing the variations, they decided to use #4 steel rebar reinforcement.

While this option provided the highest level of structural integrity, it required alerations to the design. Rebar must be covered on all sides by several centimeters of concrete in order to prevent rusting. When printing around the rebar, the designers therefore changed the single-line concrete profile to a double line.

This increased each chair’s weight, making the seats harder to roll than initially intended. Despite this, HANNAH believes the revised design represents a good balance between safety, aesthetics, and flexibility of use.

The fabrication process

With the design finalized, the team set about fabricating the rebar profiles that form the spine of what they affectionately dubbed “the dogs.”

The concrete was then printed around the rebar layer by layer. The team filled the center with gravel to support cantilever surfaces and maintain the form while the concrete cured.

The chairs at 1, 8, and 28 printed concrete layers. Credit: HANNAH

After the chairs were printed, they were covered with a tarp to keep them hydrated while drying. This technique, known as wet curing, prevents premature cracking of the surface.

Twenty-four hours after printing, the concrete had set enough to allow the pieces to be moved. HANNAH’s team removed the gravel, then set the chairs aside to finish drying—a process that can take one to two weeks.

Once the concrete was fully set, the team painted one side of the chairs in shades of green, a nod to their outdoor destination. The rest of the surface will remain uncoated.

The chairs will soon be loaded onto a 26-foot-long truck and driven—by Zivkovic—to Queens, where they will be placed throughout Socrates Sculpture Park’s five-acre site. HANNAH will also transport the printer to the park in preparation for a public demonstration on July 11 and 12.

Check out HANNAH’s making-of video below, and come see RRRolling Stones for yourself this summer.

Explore

Folly 2015: Torqueing Spheres

A look at the winning entry of the Folly 2015 competition.

Hou de Sousa introduces Sticks

Designers Josh de Sousa and Nancy Hou discuss their winning entry for the 2016 Folly/Function competition.

Fabricating Circle Shade – 2πR4

Designer of the winning Folly/Function competition entry discusses her fabrication and making process.