Dynamic mediums: The design and fabrication of Torqueing Spheres

Delve into the design, materiality, and fabrication of Torqueing Spheres through a process photo essay and interview with the designers.

Simon Kim and Mariana Ibañez, principals of IK Studio

Folly is a competition co-sponsored by The Architectural League and Socrates Sculpture Park that invites emerging architects and designers to propose contemporary interpretations of the architectural folly, traditionally a fanciful, small-scale building or pavilion sited in a garden or landscape to frame a view or serve as a conversation piece.

The 2015 winning entry, Torqueing Spheres by IK Studio, explores the structural integrity and material performance of cold-bent plywood and the process of off-site fabrication. Explore the material and tectonic qualities of the Folly, the mode of production, and the assembly of the pieces through a photo essay and discussion with designers Mariana Ibañez and Simon Kim:

FORM

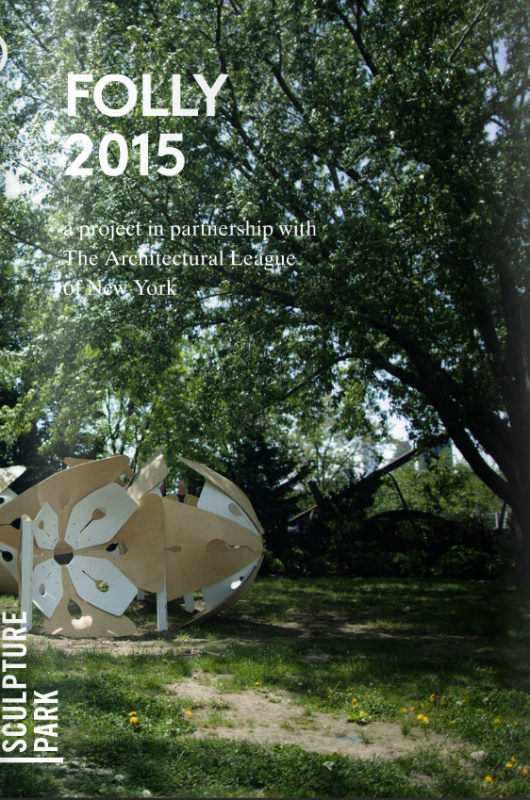

Torqueing Spheres by IK Studio | Photo by Kordae Jatafa Henry

Mariana Ibañez: Viewed from a distance, Torqueing Spheres is a winding form that shifts in and out of place — a sequence of domes, or monocoques, split in half. There’s a moment as you approach when it looks like a straight wall; as you get closer you realize it turns. The piece can be seen from both sides. Our idea was that one side creates an interior space, or something that could be perceived as an interior, while the other is more of a wall.

Simon Kim: We were inspired by domes and, in particular, their strange corollary geometry called pendentives. They are the areas where a circular dome meets vaults. Our core question was how to torque a sinusoidal line, or sine wave, through two straight lines.

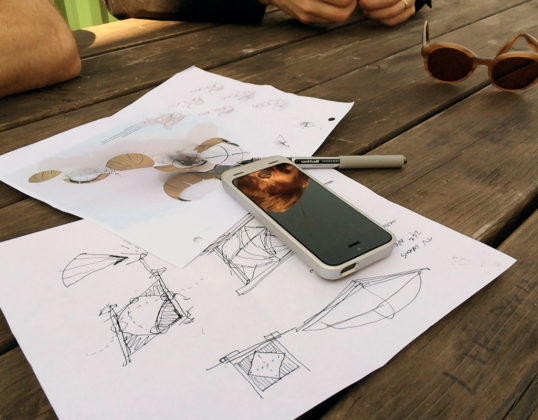

Early sketches on material curvature | Photo by IK Studio

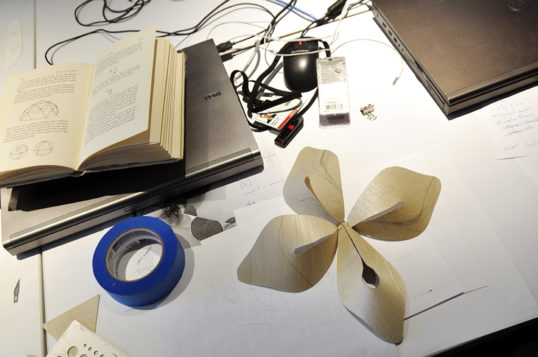

Developing the curvature through an early prototype using craft veneer | Photo by IK Studio

Ibañez: The parameters we were looking at are form, material performance, and structural performance. We are interested in general in dynamic mediums or mediums that somehow are active.

We created a gradient, or an ascending sequence, in the size of the domes. We were trying to figure out how the geometry is resolved through the same pieces as they grow taller, from child-sized to adult. Each piece needed to transform to match to the piece next to it, so the inner, painted layer repeats and remains constant, while the outer, natural birch wood layer always changes in reaction to moisture content and temperature.

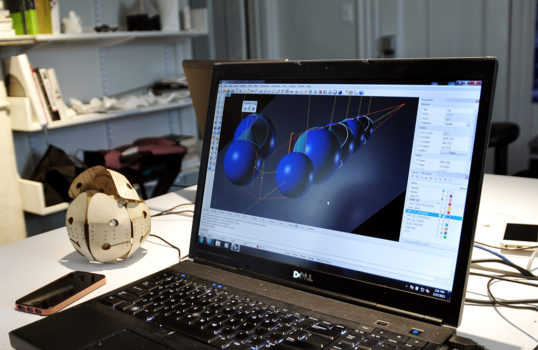

One of many computer models illustrates the geometry of the ascending sequence of domes | Photo by IK Studio

MATERIALITY

Kim: Torqueing Spheres is part of a longer material study that we’ve been doing on a method called cold bending. This is the third time that we’ve bent with some success: we previously used the process for pieces in Toronto and Calgary.

Test of a compliant mechanism for cold-bent plywood | Photo by IK Studio

We used 5-ply Baltic birch plywood. In hot bending, you steam wood and then clamp it into a form, locking it into place. But with cold bending, you bend the material as is and then mechanically fasten it so that the stress in the material creates structural integrity. The wood is in tension the entire time — it wants to fly apart, but it’s fixed and therefore rigid. It can support a massive amount of weight, far more than if it were just laying planar.

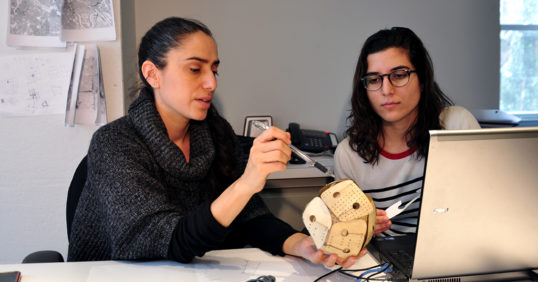

Simon and Mariana test the structural integrity of the cold-bent plywood | Photo by IK Studio

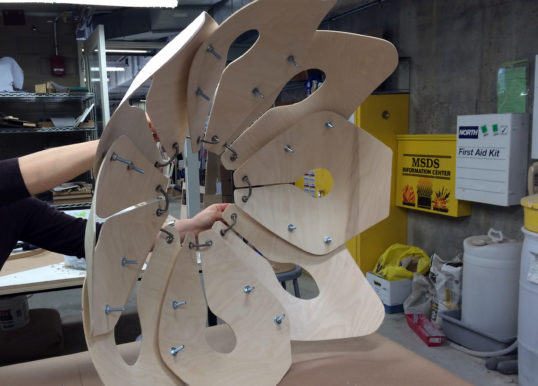

Through this process we learned that there are two variables in cold bending: the thickness of the material and the size of the hole that you must void out of the center. When we scaled up to thicker material, that hole became more and more important — its size influences how much the wood will bend, so moving between crescent-shaped holes and stretched-out ovoids determines what the radii of the bent piece will be.

Ibañez: So our panelization strategies related to the material properties and the assembly of ply. The third variable was the direction of the wood grain. We broke a lot of pieces just because the grain put up a lot of resistance. When we tried the first mock-ups, we discovered that for bigger pieces, at 1:1 scale, the grain didn’t matter so much; it’s more relevant for smaller ones.

In the end, what determined the size of the biggest dome was the largest standard sheet of plywood that could make a panel for the dome, and the size of the mill bed. In this case, because of the size of the piece, we could not go thinner than 5-ply. But when you do models with cardboard or veneer, of which we made many, you can have a lot more holes and bend these things an incredible number of times.

Mariana works with another member of the design team on an iteration of the dome’s structure | Photo by IK Studio

A chipboard prototype to test the curvature | Photo by IK Studio

Kim: The craft veneer we used for the smaller prototypes only comes in 3-ply, which offers less resistance, whereas at 5-ply, there’s a kind of isotropism or evenness to the material. We looked into marine-grade plywood and something called Wacky Wood, where all the veneers run in the same direction, but they offered little to no resistance.

A key property of wood, as a compliant mechanism, is that it can open and close forever. Wood doesn’t experience fatigue like metal; it’s not going to open and close a few times and then break along the crease.

Ibañez: Some of our formal discoveries apply to other sheet materials as well. Our piece in Calgary, for example, was in aluminum. We sometimes worry we will be seen as “the plywood people.” What is of particular interest to us is how material adheres, or conforms, to a formal principle.

Kim: Mariana is raising an important point: we are not in love with plywood per se. Our core interest lies in how to formally create curvature out of planar material, which is not exclusive to plywood.

PROTOTYPING

Kim: We made a lot of digital models in parallel with our material studies. Mariana can show you an office full of broken small plywood prototypes. Through trial and error we found the best strategy for creating that aperture.

Learning from Buckminster Fuller | Photo by IK Studio

Ibañez: These kinds of projects are a great opportunity to test things. We tried pure circles of many different sizes, and then we tested less symmetrical cuts with the circles. Basically we would take a piece of any flat material, lay a grid on it, and measure. We could translate those measurements into the computer, but the bending is actually much more difficult so we don’t have an exact digital model of anything. We are trying to create an intelligence that we can use, to learn how we might simulate this next time. And most of that comes through physical modeling and prototyping. We made some double-curved panels, with two circles within the same panel — one moving in one direction, and one in the other. We didn’t end up using those here, but now it’s part of a kind of a catalog.

Testing the compliant mechanisms in a prototype | Photo by IK Studio

Kim: Our desire was to systematize the fabrication of these domes and build a body of knowledge about cold bending — not just cut things and hope they stayed upright. Ad hoc or empirical discoveries should become disciplinary articles of knowledge, to be scaled or repeated in series

STRUCTURE

Ibañez: The domes are structural; they are self-supportive monocoques. The way that the layering works, the rubber gaskets distribute some of the load between the domes, so the whole piece is not just elements hanging from columns, but a structure that transfers loads all throughout the surface.

The rubber gaskets between the plywood layers help to transfer loads | Photo by IK Studio

Kim: It becomes structural through cold bending; it would stand up without those posts. The posts keep it from being picked up and moved. Having said that, in the past weeks the wind, rain, and visitors would have surely relocated Torqueing Spheres into the East River. Buro Happold NY was an important resource for right sizing the steel posts by determining the lateral loads and live loads of “vigorous” human play.

A late model shows the overlapping layers of wood | Photo by IK Studio

Ibañez: The technique that we used was an extension of our research. We started looking at Buckminster Fuller, who patented a particular method called self-strutted plydomes. There is an organization that underlies every geodesic dome he did, a rigor that maintains an underlying principle whether it scales up or scales down. He also worked with plywood domes at about the same scale as Torqueing Spheres, although we aren’t trying to ape Fuller; his panels follow an icosahedron logic, which does not work along the curvature we wanted.

DESIGN DEVELOPMENT

Kim: There were some pragmatic issues that made us decide to shift to a more open form; in our kick-off meeting we were advised not to have benches within the domes. But in terms of the formal language, it’s exactly the same plan. Originally, one part was plywood and one part was polypropylene, but the polypropylene was not as strong as we thought it would be and we did not want to sacrifice quality of construction and durability.

The original design for Torqueing Spheres, from the winning competition submission | Image courtesy of IK Studio

When it came to finalizing the design, there was a lot of this basketball-type paneling that happened simply because of the way we were 3D modeling at the time. We wanted to unify the strategy for bending and not make it just pure figuration. We worked to make a systematic dome or shell, in which each piece is elegantly formed.

Ibañez: Changes often occur from competition to construction phase in development with clients. We were in constant contact with Socrates during the project and its evolution. Because we are the ones engaged in the process, we are so close to it that at some point we didn’t even feel that was such a huge change — the resolution of the panelization was the big impact. Once we had our scale model finished, we started understanding the strategy for the panels as repeating the same form but producing a very different effect.

The final scale model for Torqueing Spheres | Photo by IK Studio

One of the things that we liked a lot in the translation between the images that we presented for the competition and the actual piece was that in developing a strategy for mechanically bending the wood, holes and slots were introduced that created a collection of windows not found in the original piece. The porosity allows you to see the trees and the river in the background, which serves to both connect and disconnect you from the surroundings.

One element from the competition scheme that I really wish we could have included is the second sphere on top. I think the jump in scale was pretty dramatic, and I wanted to experience that. We were imagining what the shadow would be like there. Technically we know how to produce the dome — in terms of its curvature, the layering, and attachment from one dome to the other dome — but we felt it was a safety issue.

FABRICATION

The birch plywood was cut by a fabricator in Queens | Photo by IK Studio

A stack of the final plywood leaves, before being trucked to Socrates Sculpture Park | Photo by IK Studio

Ibañez: This project falls more under the category of fabricate rather than cutting and building piecemeal on site, it was a lot of assembly of pieces. It was growing in different places before anything was visible on site; the construction process started long before we started installing on site.

The shed at Socrates Sculpture Park where the plywood leaves were bent and fastened into domes | Photo by IK Studio

Kim: I would say 75% of this project consisted of design research and development that we did in Philadelphia and at Harvard. Once we could predictably guarantee that we were going to have the same results, we sent the cut files to a local fabricator, who then sent the cut materials to the site. Once at the site we just did what we already knew was going to work.

Trimming the bolts | Photo by IK Studio

Trimming the bolts | Photo by IK Studio

Ibañez: Architecture is always preoccupied with the question of how to build — how much work needs to happen on site, how much can be premade, and what technologies can aid that. Certainly we are part of a community that engages the design and fabrication interface.

A stack of finished plywood domes | Photo by IK Studio

INSTALLATION

Finished cold-bent plywood domes, awaiting installation | Photo by Varick Shute

Kim: The Folly competition includes a residency at Socrates, so we embraced that and worked outdoors in the sun, with the elements, and all that entails. Things get dirty really fast, but we weren’t trying to keep it pristine.

Carting the largest dome down the path for installation | Photo by IK Studio

There’s also some imprecision. If you are in a lab space like we have at school, you can have the inner layer and the outer layer perfectly match, because you assemble them in a clean room where you fold it as needed. When you are outdoors, you are really just trying your best to get things to line up and put the bolts through.

Pounding the steel supports into place | Photo by Varick Shute

Fastening a plywood leaf to the support | Photo by Varick Shute

Ibañez: The piece is outside. I think as architects we tend to be very precious about these things — even the way we treat our models in the office, carefully sanding and dusting them. Well, the model might stay cleaner than the actual installation.

Three of eight domes installed | Photo by Varick Shute

We wondered how the public would engage with this thing. We imagined some people would just look at it like a sculpture, and then you have the children, dogs, and curious people of the world. Today I saw a footprint on one of the domes. Maybe that’s what it is about — this whole thing will end up disappearing in the park with stains of all sorts.

Mixing concrete for the support footings | Photo by Emily Schmidt

Mixing and pouring concrete after half of the domes were installed | Photo by Emily Schmidt

Tools of the trade | Photo by Emily Schmidt

NEXT STEPS

Kim: The first goal is to write a research paper on cold bending plywood for doubly curved shells, its structural performance, and how to digitally simulate that. Right now, there is no software tool to design and assess how wood bends and holds its shape and what kind of forces can be applied. And there is no physics engine in the computer that can do it.

Ibañez: In thinking about potential or future applications, there are many questions: could we get other materials to behave like this? How much can we push the issue of scale — can we build things that are really big? Can we build permanent structures with this strategy, or is it something that has to be temporary or reserved for interiors?

For this piece, all the plywood was the same thickness. Before building, we were wondering if the smaller domes could be thinner, because obviously the wood puts up a lot more resistance when bent into smaller pieces. So, we’d like to try going from the thinnest material to the thickest material available. This would allow different curvatures: from super curvilinear, almost like a closed figure, to something that will have a minimal, shallow arch.

A lot of our work is about the relationship between analog phenomena and digital phenomena and the transfer from one to the other. Perhaps we can figure out ways to model these properly in our digital environment and at some point create our own tools to measure the behaviors that we were not able to with this. We had to build everything to understand how it worked.

The site, along the East River in Long Island City, before installation | Photo by Varick Shute

Torqueing Spheres by IK Studio | Photo by Kordae Jatafa Henry

Torqueing Spheres is on view at Socrates Sculpture Park in Long Island City through August 30, 2015. Read more in the Folly 2015 feature.

Torqueing Spheres was designed by IK Studio: principals Mariana Ibañez and Simon Kim with support from Chris Johnson, Iman Fayyad, and Charlotte Lipschitz. Structural consulting by Gustav Fagerström and Michael Steehler of BuroHappold. Fabrication by Tietz-Baccon. Recycled material from William Blaise Dufala and RAIR Philly. With support from PennDesign and Harvard GSD.

Explore

Folly 2015: Notable entries

Sophie Elias surveys themes that emerged among the 2015 Folly submissions.

Folly 2015: Torqueing Spheres

A look at the winning entry of the Folly 2015 competition.

In conversation: Mariana Ibañez and Simon Kim with Elissa Goldstone

The winners of Folly 2015 engaged in an email conversation with Elissa Goldstone, the exhibition program manager at Socrates Sculpture Park.