Machine means and architectural ends

HANNAH uses technology as a tool for creating new architectural languages.

June 8, 2020

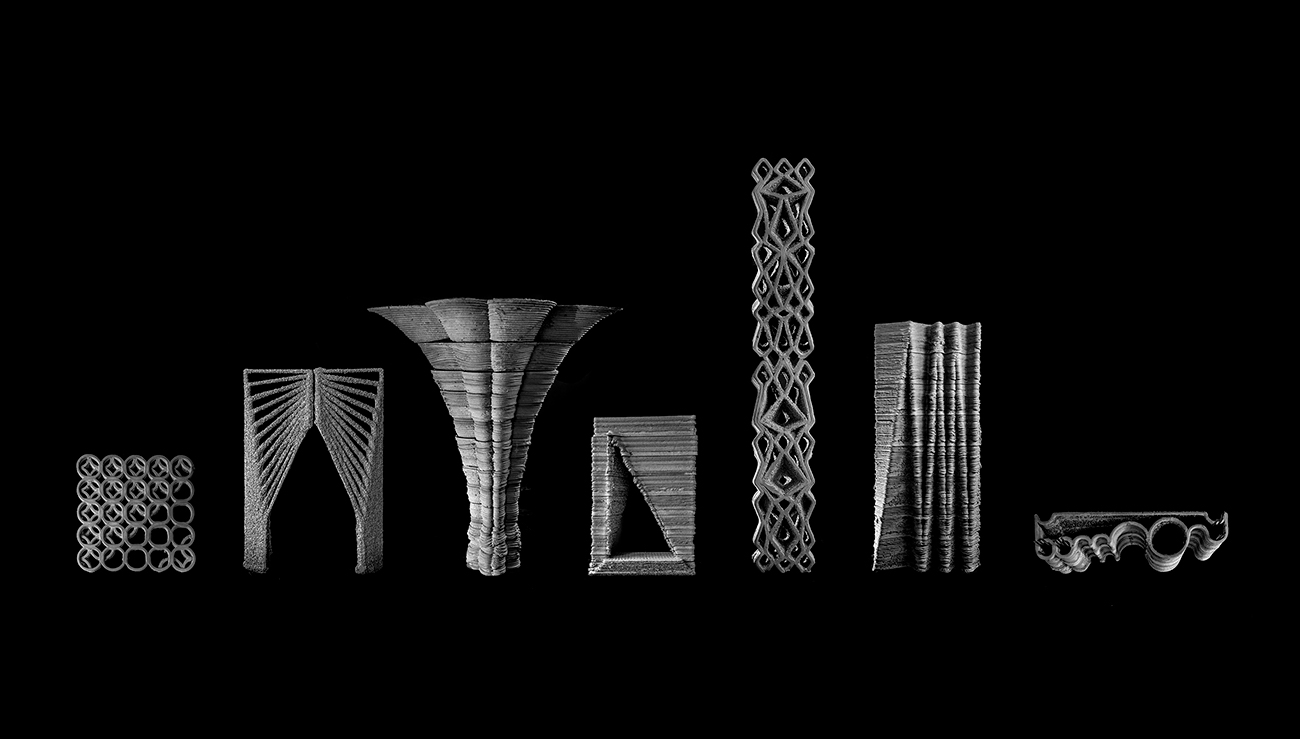

Proto-architecture of Force Column, from HANNAH's Additive Architectural Elements project. Credit: Jeremy Bilotti

HANNAH is a 2020 League Prize winner.

In the work of Ithaca-based HANNAH, construction processes and material tectonics are informed by an interplay between experiment and precedent. The League’s program director, Anne Rieselbach, spoke with principals Leslie Lok and Sasa Zivkovic.

*

Anne Rieselbach: With each project, whether it’s a scale detail, furniture, or house, you’re reinventing the building process, in a sense. Can you talk briefly about what initially inspired your practice?

Sasa Zivkovic: I think HANNAH explores how new technologies inform architectural design at a fundamental level. We believe that new types of construction also enable new ways of thinking about architecture. In some ways, one can trace that idea to earlier instances—the development of reinforced concrete or steel, etc.

Of course, we also have to acknowledge that this always goes hand in hand with other influences; technology is not the only lens through which we approach architecture. But we did notice a gap between research labs, where one develops prototypes and new material applications, and practice. So our goal was to create a platform where we could implement new material and tectonic explorations from the ground up to then inform the design.

This requires, in our case, a series of tools. When we first started, the tools weren’t available. The building industry wasn’t really set up yet to allow for this kind of research. Out of necessity, we had to become inventors and makers of our own tools.

Rieselbach: Did your time studying at MIT inform your practice?

Lok: Yes. As first-year MArch students, we were asked questions like, “How does your building touch the ground if you’re using this particular type of material or aggregation method or building system? How does it turn corners? How does a vertical wall transition to a horizontal ceiling?” From early on, we were prompted to consider these basic but important architectural strategies or languages, and to think about how material and its articulation relate to the construction aspects of architecture.

Zivkovic: Concept was always discussed within the context of technology. MIT was formative, to some extent, because it exposed us to hacking and making at the technology level.

During our time here at Cornell, we’ve reflected on these technologies and tried to find new ways to translate them into architecture.

Rieselbach: What guides your fabrication decisions and material experimentation? The tools at hand? Some interplay between the two? How do you initially approach a problem?

Lok: Initially we were interested in 3D printing concrete because it fundamentally challenges a type of construction method. Back in 2011 we bought an open-source RepRap 3D desktop printer kit. We spent the Christmas break putting the machine together. That seeded our interest.

We collaborated with a Chinese 3D printing company quite a few years back, but they were unable to print some of the designs that we proposed. That led us to build our own full-scale 3D printer. Sasa taught an option studio at Cornell and used that as a pedagogical opportunity to use open-source technology to scale up the logic of a desktop 3D printer in order to construct a full-scale printer.

3D Printer at Rand Hall, part of Cornell's College of Architecture, Art, and Planning. Credit: Jeremy Bilotti

That was the first step. The next part was developing the material mixture. The printer itself was straightforward, to some extent, but the concrete material was actually quite challenging. It took us a summer to go through different printing failures and eventually achieve a workable recipe.

Once we had a material to work with, we were able to explore architectural constraints and opportunities. Material experimentation became really important in informing the discovery of a different architectural vocabulary or language, and when asking the question of how we might design or build differently.

Zivkovic: It’s interesting—we often encounter this chicken-and-egg question about the relationship between the bottom-up material processes and the top-down decisions one has to make in an architectural project. With one of the earlier projects, Additive Architectural Elements, we were fascinated by the material methods to begin with, and it was a top-down decision to say, “Okay, we want to explore 3D printing at full scale, because we have seen some examples of how it has been done elsewhere, and maybe there is something we can contribute.”

Rieselbach: A part of your research is centered on re-envisioning prototypical architectural elements such as columns, doors, and windows through the medium of 3D printing. What are some of the structural and formal qualities of 3D printed concrete that require and inspire new solutions?

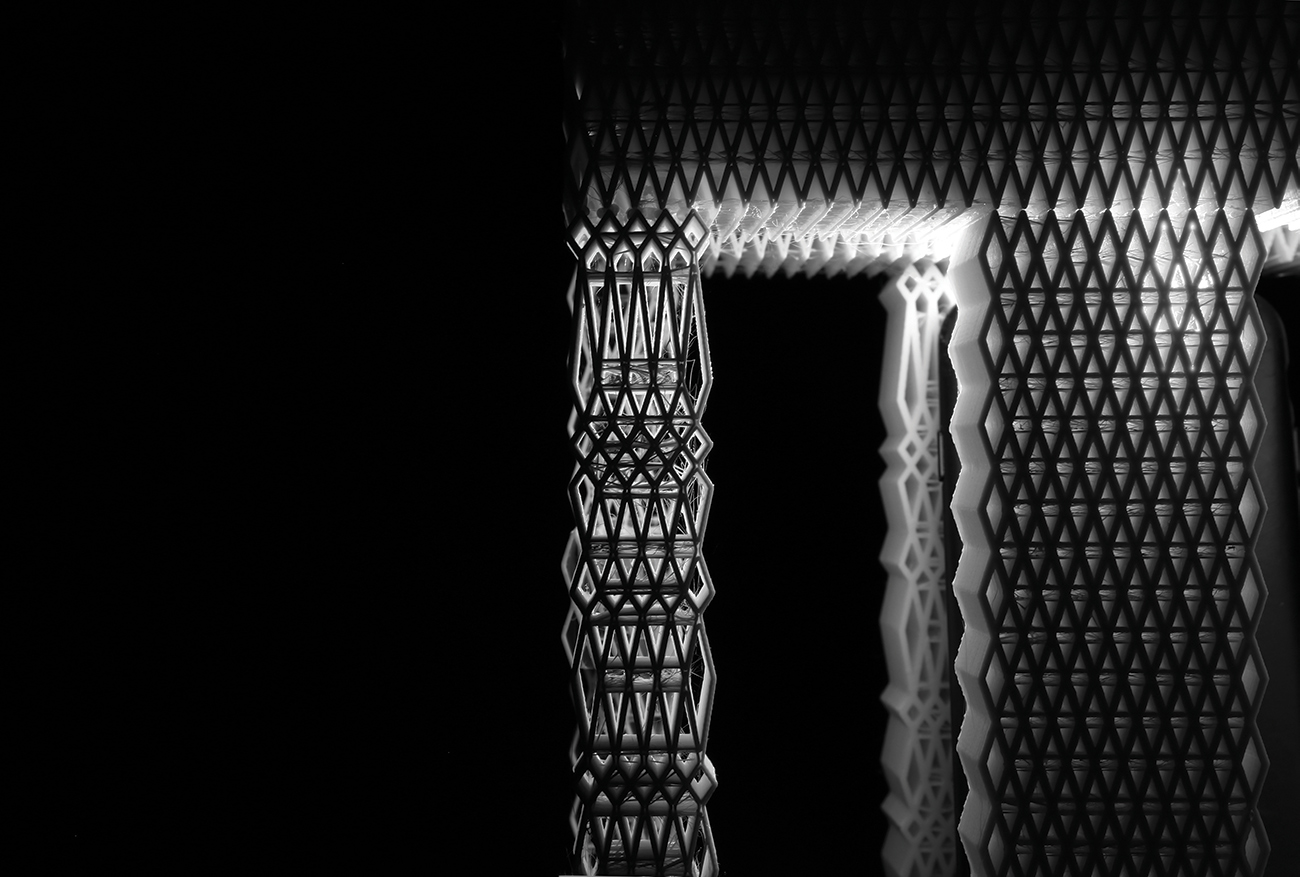

Zivkovic: This is an interesting question, because the assumption is that one can just design something and then print it. But we discovered one cannot print just anything. The 3D printer is a machine with very specific requirements, with its own rigor and design logic. So in Additive Architectural Elements, we asked the question, what is the tectonic and spatial opportunity of 3D printing? Essentially, what is the language of 3D-printed concrete?

Lok: One example we like to use is the window. One cannot print a beam in mid-air without something supporting it underneath. That makes printing a rectangular window opening impossible. But the printer can corbel, incrementally creating small cantilevers to generate form. Therefore, 3D printing a window following this logic might play out in a triangular opening instead of a rectangular one.

Zivkovic: This is something that we’ve played out in this project through the investigation of a series of prototypical building elements: a column, a wall, a window or door, another column, a floor or a ceiling. We looked at how 3D printing as a material process changes the way we have to think about these prototypical architectural elements.

Lok: We decided to explore these simple elements as a way to delineate the specific constraints and demands of each—the structural and functional demands, along with the material and printing constraints. Making new forms in relation to those specific demands was fascinating to us. Rather than immediately design a building, we asked, what are some of the basic requirements for a column, a ceiling, the floor, and so on? We simplified the project into a series of basic elements in order to discover their design potential.

HANNAH exhibition at Pinkcomma Gallery: "Additive Architectural Elements: A New Robotic Brutalism." Credit: HANNAH

Rieselbach: You’ve used the terms “Doornament” and “Floornament” to describe the decorative and structural qualities of some of these elements. Can you expand on this?

Lok: We know that the 3D printer has multiple advantages, and one of these is mass customization. The printer does not care if you print a part the same way 100 times or differently 100 times. This is something we can leverage—the printer even enables, perhaps, a degree of exuberance.

This is where ornamentation comes into place. In Additive Architectural Elements, form and ornamentation became key architectural narratives to explore beyond the efficacy of 3d printing. There is structural ornamentation, such as in the Force Column. We also have program ornamentation that plays out in the ceiling elements, and ornamentation for the sake of pleasure in the Floornament and Doornament, where we play with patterning and transparency. Part of the exploration was also about being playful. Similar to playing with syntax, we designed 7 versions of each element, for a total of 49 elements.

Rieselbach: In your League Prize entry, you describe the potential for new environmental practices associated with digital design and fabrication technologies. Can you give some examples of the potential for material savings afforded through 3D printing, both methodologically and structurally?

Zivkovic: One of the paradigm-shifting aspects of 3D printing is that there is no formwork. In a normal cast-in-place building, one essentially builds the building twice. One has to build the formwork, then put the rebar in, then cast the concrete into it. In 3D printing, one prints the concrete directly into shape. That fundamentally changes the way one operates with concrete. This is essentially an opportunity to save materials.

There’s a second point to all of this, which is the possibility for waste reduction at the material level. The 3D printer can place material where structurally necessary, as we’re doing in the Smart Poché Wall or in the Force Column elements. This goes back to Leslie’s point about mass customization. We can optimize a building with regard to its structural requirements, and the printer can deposit material where it’s structurally necessary—so we can save material.

Of course, this sort of calibration of structural density is a form of design exploration, and we’re using this as a playful motif in the Architectural Elements project to explore the spatial, formal, and architectural potential of such an approach.

When thinking about the potential for new environmental practices more broadly, however, it’s important to add that concrete itself is problematic. Some of the strategies we’re using mediate its impact. But in the long run, we need new 3D printing material mixtures that will enable us to fundamentally rethink concrete. This doesn’t happen enough yet.

This is something we’re interested in pursuing as a research project, and something that we have started, but it’s part of a much broader discussion within the building industry. Concrete itself needs to change if architects want to continue working with it. So it’s good that 3D printing saves material, and there are certainly some advantages to it, but one needs to be cautious of hyping this technology.

Rieselbach: What do you mean by the goal outlined in your League Prize portfolio: “to mine the tension between machine means and architectural ends across scale?”

Lok: Sometimes we have to explicitly say that we’re not technologists. Ultimately, we are interested in architecture.

As Sasa mentioned, there is a top-down and bottom-up process that we are playing with in our design explorations. It goes back to the chicken and egg: At what point do you let the tools drive the design? At what point do we, as designers, intervene or make design decisions?

I think there’s a balance between the requirements and the idiosyncrasies of the process, as well as between the tools that we use and our design thinking. Other considerations, like precedent, program, and environmental concerns, then feed into the narratives of the design process.

Rieselbach: Everything you’ve described is about careful calculation more than anything else. Are there elements of chance and surprise, and how do you deal with them?

Lok: There are definitely many surprises. Since these are experimental processes, one cannot anticipate the end result or always be in full control. A large part of what we do is design through making, with each iteration fine-tuning and calibrating what we discover.

We don’t start out knowing exactly what to do with, let’s say, the slicing of logs. We have a basic idea; we can develop the process and protocols that allow us to follow the natural geometry. But that is not a means to an end. We continue to explore, for example, what happens if we start to vary the thickness when slicing. Then it becomes really interesting. When we started to play with the thickness of the cut, we produced a different curvature that was informed by the original log but allowed us to create new exaggerated or subtle curves.

There is no rulebook. We’re constantly discovering new surprises and new design opportunities.

Zivkovic: It’s a dialogue between the machine, with its constraints, and our own personal obsessions, biases, and opinions. So there isn’t an entirely rational process, or a process based only on metrics. A lot of other influences drive the work.

This is what distinguishes us from a research lab. The practice gives us the freedom to explore issues that are not as easily quantifiable.

Explore

Drawings and intent in American architecture

Excerpts from the book's introduction by David Gebhard looks at themes of style, intent, and value in architectural drawing, situating these works in relation to "high art" of the 19th and 20th centuries.

GLUCK+: Thinking making making thinking

The partners of New York City-based design–build practice GLUCK+ discuss recent residential and education projects.

Interview: The Living

David Benjamin employs prototyping, research, and an open-source ethos to bring architecture to life.