Linking Architecture and Industry in Michigan

The work of Ann Arbor firm PLY+ is deeply influenced by Midwestern manufacturing traditions.

PLY+ is a 2021 Emerging Voice.

The practice of Ann Arbor, Michigan, firm PLY+ has been shaped by close collaboration with the manufacturing community in the Detroit region. The League’s Sarah Wesseler spoke with partners Craig Borum and Jen Maigret.

*

Can you give me an overview of how Michigan’s industrial context has affected your practice: the way you think, the way you work?

Craig Borum: We’re both transplants from the East Coast. We ended up here in the Midwest through teaching appointments at University of Michigan.

When I arrived in the late ’90s, the digital was becoming much more part of the daily practice of architecture, but I found myself struck by how technology was already part of the everyday landscape in this industrial context. That realization pushed us to examine how we could take advantage of the skill of making here.

It was also interesting to experience the dichotomy between, say, Ford at one end of Woodward Avenue in Detroit and Cranbrook Academy at the other end. The two represent an ideological opposition, with Cranbrook seeing handicraft as a virtue and Ford focused on mass production and access to technology.

Woodward Avenue, Detroit, in the 1940s. Cranbrook Academy and Ford’s former Highland Park Plant are both located on the street, separated by approximately 14 miles. Credit: Public domain

That dichotomy was super exciting for me, coming from an architecture craft tradition—thinking about how those things could begin to come together with the digital tools we were now able to access.

So much of the early work we did as a practice was about using projects as an excuse to play with tools. Planning out a project was kind of secondary to advancing our skill set.

Dolomitic limestone for St. Mary Chapel at stone fabrication facility in Wisconsin. Credit: PLY+

You’ve done a lot of collaboration with local manufacturers. Can you say more about what that looks like?

Borum: The auto industry, over its history, has gone from a vertical manufacturing approach to more of a horizontal one. Starting in the ’80s or ’90s, lots of small companies were being used to farm out different aspects of production. The area around Detroit is full of these small companies that might make one particular part and have a tooling setup completely geared toward that.

When the auto industry hit a rocky road, we were able to break into some of these workflows and access workshops during gaps in production runs in order to produce small, one-off things: Putting a piece of stone on a waterjet cutter that was geared toward cutting steel, for example, and playing with what we could do in terms of manipulating materials.

A lot of these tools are now pretty ubiquitous: CNC routers, waterjets, small degrees of laser cutting and digital production. We’re finding it much easier to tap into some of those things now.

Detail of robotic routing tool and tool paths on underside of the altar for St. Mary Chapel. Credit: PLY+

Jen Maigret: That trajectory has transformed a bit now that we’re scaling up in the work. While the early days of PLY were about literally going to shops and standing with people as they used the waterjet cutter to understand how it works, now we have less direct engagement in some of the making due to the scale and the structure of the relationship with the general contractor or CM.

Software has also changed our workflow: parametric tools, building information modeling software. We’ve been increasingly exploring ways to foster collaboration with makers on larger projects by rethinking how we communicate the design intent, mainly by expanding our approach to construction documentation.

The St. Mary Chapel is a clear example of both scales of engagement with makers. On the one hand, for the liturgical elements—the altar, the stand for the tabernacle, and the ambo—we were traveling to Madison, Wisconsin, to learn how the stone carving worked. We went to the quarry and picked out the stone.

And on the other hand, with the brick, it was a partnership between us, the GC, and the masons. This happened both through digital technologies—passing our model to them, them passing the model back—but also a lot of onsite work, trying to figure out how to run the plumb lines and set the stage for building project. Onsite, we took advantage of old-school methods, like one-to-one scale printouts of the rotation of the brick, as well as newer ones: By using an iPad, we were able to turn the different layers of the brick coursing on and off one by one.

Davenport Masonry masons led by Mike Piazza utilizing plumb lines and onsite digital model to build the complex conical corner at St. Mary Chapel. Credit: PLY+

So you were able to collaborate with the masons by sharing digital files. Is that typical? Are people in different fields syncing up in terms of their use of technology?

Maigret: Yeah, there are pretty interesting improvements in terms of the technologies of models that we share, and the tools of working as well. There are robotic masonry machines in use for full-scale construction, so we explored this potential for the chapel, but there are limitations in terms of reach that prevented their use for this application.

That’s led to a research grant funded through Taubman College’s Prototyping Tomorrow Program that we’re currently working on. We’re using augmented reality software that allows you to basically see the digital template that guides the actual physical placing of bricks.

Masataka Yoshikawa testing a mixed reality HoloLens 2 as a tool to guide the construction of complex brick patterns. Credit: PLY+

Next summer we’ll be back in person with the masons building experimental brick walls, but with a thermal outcome in mind. We’re looking at ways that the tools of patterning we explored at the chapel can be leveraged to improve thermal performance of brick walls.

So basically, you’re not only tapping into historical forms of making, but also collaborating with people who build or manufacture things to co-create new forms of making.

Maigret: Co-creation is a great way to describe a lot of what we do. That happens with our clients; we place great importance on regular meetings, to make sure that everybody’s perspective and all the different knowledge is coming together. But we also use a co-creation model with fabricators whenever we can. The more communication and overlap we have, the better off the project is.

Quarra Stone Company stone carver hand-finishing the ambo stand for St. Mary Chapel. Credit: PLY+

Could you describe the role research plays in your firm more broadly, and how this relates back to these regional traditions?

Maigret: This is a really active conversation in the office. In the last few years, we’ve been trying to find overlaps and parallels between materially driven research grants that we can compete for through the university and our client-based projects.

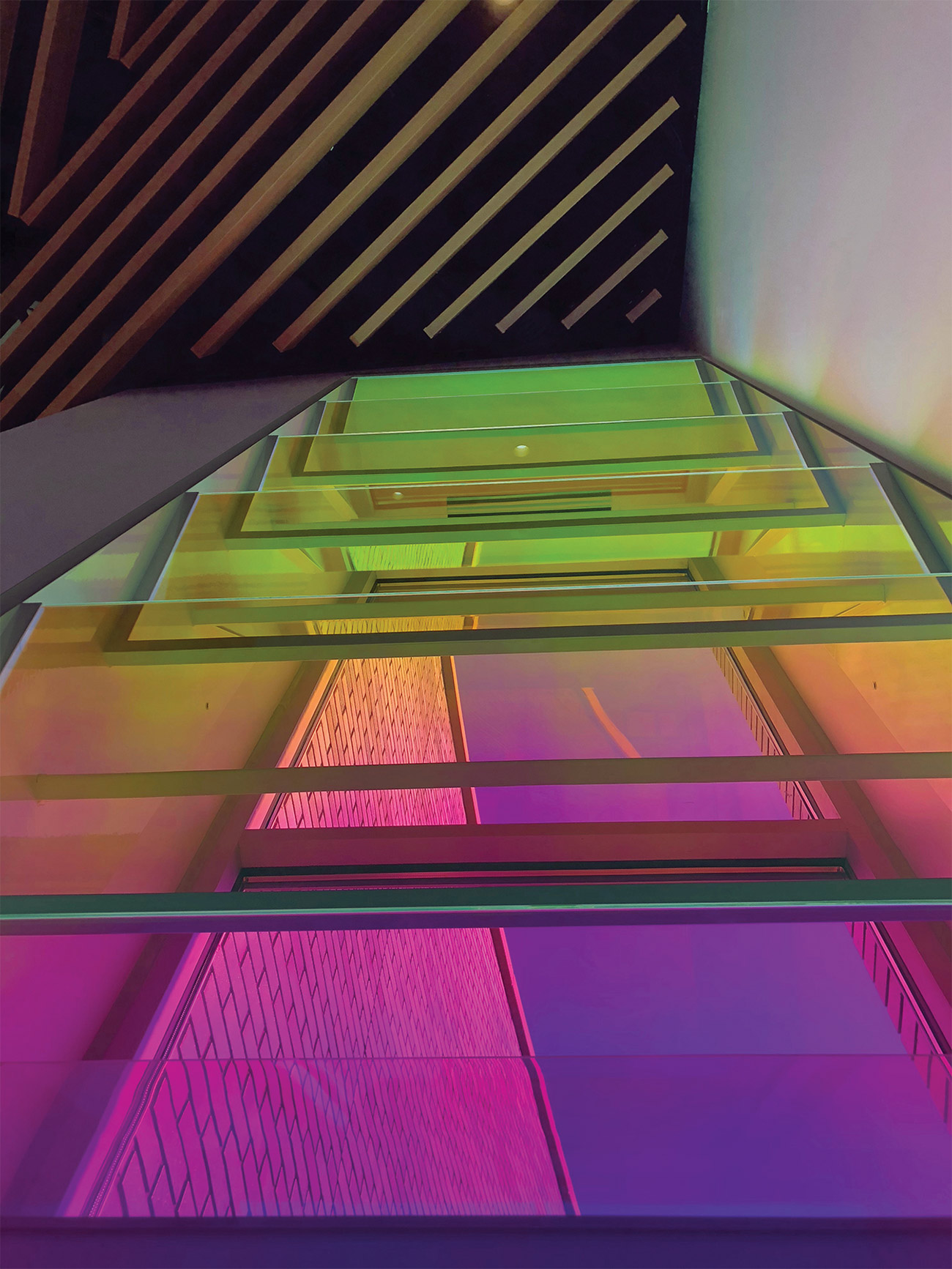

The chapel is an example of this. Initially, when we were competing to win the commission, we presented ongoing research on dichroic glass to the interview committee. While this research project was exploring the use of dichroic glass to improve environmental performance characteristics in a specific retrofit context, we spoke about how the lessons we had learned from a recent manufacturing plant visit could play a meaningful role in the chapel as an interpretation of stained glass window traditions. In particular, we were interested in the glass manufacturing lab’s ability to develop dichroic glass recipes that had predictable influences on how the visible light spectrum was reflected and refracted as individually visible colors. The committee was very excited by this idea, and it likely contributed to us being awarded the project.

And, as we’ve discussed, the explorations of brick patterning in the chapel led us to new ideas that we wanted to explore further after completing the project, so the research grant we received allows this.

In this way, there is a constant exchange of and evolution of ideas that allows us to learn alongside the people we work with and then return to unanswered questions that offer potential to improve future projects.

The research into dichroic glass is also leading to interesting new possibilities. We were originally considering it in the context of K-12 retrofits—many of the schools in this region are in need of updates, and we thought the material had potential both to address environmental performance goals and to feed into STEAM education programs. This idea has come full circle, in a way, as some of our education clients are now interested in using the material for their projects.

So basically, your work with dichroic glass across several projects was spurred by visiting a local manufacturing plant, seeing what it was doing, and then getting excited by the possibilities this presented in terms of addressing needs in the region—things like outdated educational facilities. Is that fair to say?

Borum: Yeah. When we toured the glass factory and went through the research and development department, we had no thoughts about colored glass. We were just thinking about different ways of using glass to handle light waves, because before we were looking at creating light wells for school retrofits we were talking about greenhouses as an extension of a classroom space. And what we found out in that tour was that the factory was looking at dichroic glass at a much bigger scale, developing recipes that would allow certain wavelengths of light through the glass and reflect others off in the application of very large-scale industrial greenhouses. They were trying to calibrate the wavelengths for the plants but reduce the heat gain in these buildings, because at a certain scale and with a certain degree of exposure the conditions become almost hazardous for the workforce.

So they were doing this as an industrial solution, but for us, it was like, “Well, wait a minute, there are aesthetic properties to this.” And there was potential to apply this material at a small scale in relation to the way we were thinking about the classroom space, and about a pedagogy which could come out of a class that participates in growing things. So we were able to bring all of those things together.

And then the application of the glass in the chapel involves none of those things. It’s about a connection back to stained glass—the liturgical relationship between that and the interior of the church.

Interior view of St. Mary Chapel showing colored light cast along the sanctuary walls by the dichroic glass window. Credit: PLY+

Maigret: Our current research very much builds on the traditions of both automated fabrication and hand craft in Michigan that Craig described. Our work is really enhanced when we have the opportunity to visit the shops and other sites of making and really understand what the tools and techniques are, what limitations they have, what kind of assumptions they come with, so we can begin to challenge that. It’s this hands-on engagement that gives us a different view of the opportunities available to us in each project.

How has the maker community responded to your interest in collaborating on architecture projects? Are people generally excited to work with you right away, or does it take a bit of convincing?

Maigret: Overall, I would say most of the people we work with get really excited about having an opportunity to test their skills and apply them in a new way. Quite often it’s fun for everybody involved.

Wood “brick” wall under construction by PLY+ for Zola Bistro restaurant. Credit: PLY+

Borum: I think it comes down to the fact that most of the fabricators and makers we work with really take pride in their level of skill and their experience. When you pose a challenge to them, they get into it. Especially if we can show them that we’re inviting them to be part of the conversation, rather than “Here’s what we want to do. Do it.” When we approach them as partners, we get a completely different response, and a completely different product in the end—usually better than we imagined. Because they have skills that we don’t have. We can imagine the form, but the ins and outs of really making it work and making it happen, they have that knowledge.

Full scale mockup of custom rail assembly for the Michigan Animal Rescue League. Credit: PLY+

That was a big lesson over the history of the practice. In the beginning it was like, “Here’s the tool; let’s make the tool do what we want it to do.” Now we always walk into the situation as though we have an idea, but we’re the amateurs. We ask the pros, “How would you do this? What are we not thinking about that we should be thinking about?”

Interview edited and condensed.